Table of Contents

Hope this user guide helps you if you notice a fix for the outboard speedometer.

Updated

We’re interrupting our overland journey again to bring you anotherBlue View. Believe it or not, people like to talk about boats to talk about travel. Travel tomorrow.

In the last issue of Blue View, I talked about troubleshooting problems with engine sensors, namely testing temperature, oil pressure and water temperature. In this BV, I will talk about diagnosing difficult situations using tachometers.

Why does my boat tachometer not work?

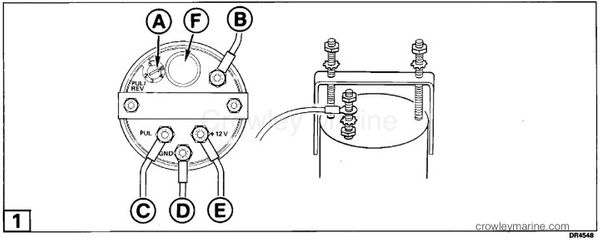

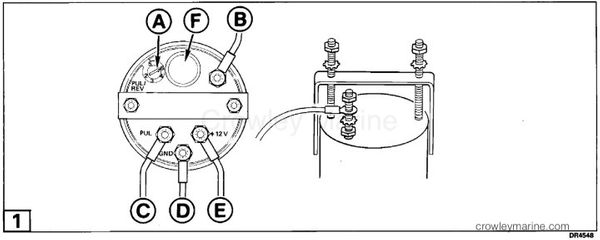

Make sure there is power to the speedometer (usually power from my rocker switch is purple wire). Make sure our own “signal” cable (gray cable) is connected. Make sure the off-road cable (black cable) is connected to the tachometer. Make sure the tachometer is set to the correct number of poles (if it is an aftermarket tachometer / multi-model tachometer).

While there are several other tachometers available for 2-stroke and outboard boat motors, gasoline engines and inboard diesel engines, they all work essentially the same: They convert all information from pulses per second to suggestions around the terminal. to engine speed.

Different types of cars generate these impulses in different ways. Some motors generate pulses electronically, at which point there is one pulse per revolution of the motor. Many internal diesel engines use an alternator source as the speed input, and the pulse per revolution knob is the calculation of the number of alternator poles, as well as the relationship of the type of alternator pulley to the size of the engine pulley. Elsewhere, a magnetic pickup mounted next to the flywheel is used that generates a single pulse for each gear tooth — in this dilemma, there are two or three hundred pulses for every revolution of the engine.

In addition to size, shape and finish, tachometer manufacturers usually offer different models for different types of engines. One approach is full range. The old Nine Cups Ford Lehman engine has a top speed of 2,800 rpm, and furthermore I don’t need a tachometer showing a red line at 6,000 rpm and a full scale of 7,000 – that’s an idle speed of 800 rpm. will deflect the needle unevenly. Another possibility is to “pre-calibrate” the speedometer. Most manufacturers show models calibrated for the most common purposes, avoiding most disputes that require special equipment and a 60 minute block or two to evenly calibrate the tachometer after installation.

Okay, enough of a walk – let’s get started.troubleshooting. Usually, four problems can arise with the tachometer: the speedometer does not work completely and always shows zero; the needle is stuck or stuck permanently; the needle is really wrong; or the speeds are systematically very distant – be they low or high. You will need an HDTV multimeter to test the tachometer.

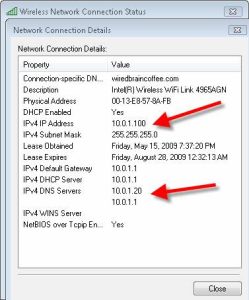

Check the obvious – under normal ignition, is there 12 VDC (or 24 VDC) between the positive terminal and the negative terminal, measured with a voltmeter? If not, use a voltmeter to see if the problem is with the positive side or surface side wiring.

If the voltage is normal, the next step is to check the input signal. Remove the signal cable. Set an AC voltmeter to volts and connect it between the signal wire and ground. Start the kernel and set the idle speed. You should get a reading from a multimeter, which depends on the engine speed. If the tachometer is connected to an alternator, our reading shouldnot less than 5 VAC, otherwise it is closer to 0.3 VAC. If you notice any signs of ripple current, reconnect the signal section, and if the problem is still evident, the tachometer itself is the most likely cause.

Updated

Are you tired of your computer running slow? Annoyed by frustrating error messages? ASR Pro is the solution for you! Our recommended tool will quickly diagnose and repair Windows issues while dramatically increasing system performance. So don't wait any longer, download ASR Pro today!

If you do not get a single pulse current indication, disconnect the speedometer signal wiring on the engine and try again there. If you see ripple current in the line at this end, the problem must be in the wiring. If not, the problem is almost certainly with the signal generator.

The needle can get stuck in the named place or place permanently for various reasons. One thing is really that the speedometer is too tight and will eventually deform from heat or vibration. Try to loosen the main clamps that hold it in place, then gently pat the front face. When the hook is released, the speedometer is tightened just enough to hold it in place.

Another simple reason the needle gets stuck is to apply an electric charge to it. This is myIt would happen, for example, if the battery cable was actually disconnected while the engine was running, I would say that the tachometer was exposed to high levels of RF noise received from an improperly tuned or grounded RF radio, earth or lightning strike. Occasionally, the hazard can be eliminated by placing the magnet on the faceplate above the needle and “pulling” the hook.

How do you test an outboard tachometer?

Start your current engine, turn on the retail tachometer, and let the engine run to 1000 RPM on the factory tachometer. Record and compare this reading to match your boat’s tachometer. If no signal is found, check the outboard operating system.

Usually the cause is a faulty display, which may be due to a bad connection. Start by shaking the engine on each wire leading to the tachometer to try and isolate the main culprit. Have someone look at the tachometer while your family members shake cables to the side of the constantly running engine.

Electrical noise could be another possible cause of erroneous readings. Does the problem only occur if the autopilot is working or emails are being sent to your HF radio every minute? Sometimes the problem can be solved by adding resistance to the signal line. It should be placed on the last rungs of the tachome wire ra. You may need to really experiment with the dimensions of the resistance. A 10,000 ohm, 1/4 watt resistor often solves problems without affecting calibration. If this is definitely not the case, try a 1k 1/4 ohm resistor, also known as a 100 1/4 ohm resistor.

This is a sign that the tachometer is not calibrated, which, of course, usually does not happen when something is changed. Have you recently changed the tachometer? Generator? Is there a pulley on a generator or on an engine? Some tachometers have multiple position switches or jumpers located on the rear panel or accessible through holes on the rear panel. Make sure the jumpers are not too loose, and if there is a button, the pins may be dirty. Try turning the switch several times each time and then returning it to its original position.

As a rule, it is not difficult to calibrate the tachometer if necessary. Many older tachometers use coarse dial switches and a potentiometer to fine tune the range or adjust the gain. If the tachometer is only off by 10-20% or Less, you can only recalibrate it with the potentiometer – otherwise you need proof from the manufacturer to set the switches correctly. Newer tachometers often use standardization software, and you need a computer, that software, and all the cables you need to set up the tachometer.

You will also need a good stroboscopic tachometer to help you determine engine speed. This is an adjustable flash with a new digital display. They used to cost hundreds of dollars but can now be found online for under $ 50. I’ve also seen smartphone and drug apps that mimic a stroboscopic tachometer, and besides, I can’t guarantee the accuracy of these apps, they are probably good enough to calibrate your tachometer to about 5% indoors. You can rent, borrow, buy real estate, buy cheap, or try any of the software applications. Then you need to pay attention to the big shkwillows on the engine frame. It can be any small piece of masking tape, a line used with a marker, a colored dot, or a colored dot as long as it is easy to see when you use it.

Start the engine and generally increase the engine speed until the engine tachometer is approximately half of the engine’s maximum speed. Set the strobe tachometer to the same rpm and point our strobe at the pulley. When the continuous engine tachometer is accurately calibrated, the mark on the pulley appears cold. Chances are, the brand is really moving. If at any point it moves around the circumference of the lever, your tachometer is only slightly calibrated. The if icon appears around the entire circumference of the pulley, your main tachometer has a lot to do with calibration.

Adjust the tachometer strobe frequency until a mark appears on the pulley so you can slow down and eventually stop. However, the electronic digital display of the stroboscopic tachometer shows the correct engine speed. Adjust the potentiometer on the backside of the engine tachometer assembly (or using tachometer tuning software) until a match is displayed as a tachometer strobe. Check normalization for 1/4 gas and 3/4 gas. In an ideal world, the engine tachometer could now match the strobe tachometer at almost three engine revolutions. You will likely need further calibration adjustments until these errors are minimized throughout the cycle range.

Now that your engine tachometer has a problem, the Nine Cups team continues where we left off, in the wilds of Swaziland and South Africa. Stay tuned …

How do you know if your boat tach is bad?

Usually, four problems can arise with a tachometer: it does not work completely and always shows zero; the needle is likely to be stuck or pinned to it permanently; the needle is undoubtedly unpredictable; or the speeds are somewhere constant – low or high. You will need a multimeter to evaluate the tachometer.

Устранение неисправностей тахометра подвесного двигателя

Fehlerbehebung Beim Außenborder-Drehzahlmesser

Solución De Problemas Del Tacómetro Externo

Dépannage Du Tachymètre Hors-bord

Probleemoplossing Buitenboordmotor

Felsökning Av Utombordares Vardare

Rozwiązywanie Problemów Z Tachografem Zaburtowym

아웃보드 Tach 문제 해결

Risoluzione Dei Problemi Del Contagiri Fuoribordo

Resolução De Problemas Do Tacômetro Externo