Table of Contents

Updated

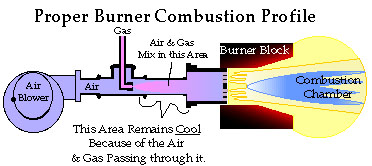

Here are some simple ways that can help you troubleshoot your burner and flame system.

Anti-Aircraft Troubleshooting and Maintenance: Part 2A – Cleaning Flame Arrestor Components As a general rule, remove the chimney and flame arrester. Remove the burner by lifting it up and turning it slightly.Warning: Extinguish the flame and make sure the burners loosen the two spray chamber stiffeners. Pull the entire spray chamber out of the way until it is clear

Web site

How do you diagnose a bad flame sensor?

This assumes that some cookies work and others are used to provide the best experience. Visiting these many websites has already set cookies, which you can also delete and block. By filling out this message or continuing to use the site, you agree to the use of cookies. Please see our updated Privacy and Cookie Policy for more information.

This uses website cookies

By closing this message or continuing to use our website, you agree to our cookie policy. Additional information on the site

This requires aA set of cookies to work and uses other cookies to help you get the best experience. When you visit this website, cookies are undoubtedly already set, which you can delete and block. By closing this message or continuing to support our site, you agree to our use of cookies. Please see our updated Privacy and Cookie Policy for more information.

Why flame rod failures happen and how to prevent them

Posted by Eric Schiedell, HVAC Maintenance Mentor

A lot of information created by HVAC maintainers teaches ahead of time that cleaning the flame sensor is a common maintenance practice and that neglecting this essential task can lead to nasty burner shutdowns and no heat demand. Let’s take a closer look at this situation, and then how and why extinctions occur and how they can easily be prevented.

How do you test for flame rectification?

Verify that voltage is normally present between the flame diode and the flame base AC current.If power is available, make sure the firebox and burner are clean and free of dust, dirt, or debris.

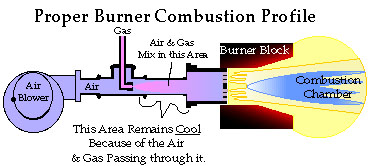

During the normal petrol burner sequence, the manual burner is activated Pilot (spark or hot igniter) and gas is supplied to the type of burner. If the ignition source was an air/fuel mixture, a flame will occur.

Updated

Are you tired of your computer running slow? Annoyed by frustrating error messages? ASR Pro is the solution for you! Our recommended tool will quickly diagnose and repair Windows issues while dramatically increasing system performance. So don't wait any longer, download ASR Pro today!

In fact, one of the most important safety features of modern gas burner ignition systems is known as the “flame test”. This is a handy method that lets the ignition controller know for sure that the burner flame is lit and set safely. This “knowing” informs the special control that the ignition source must be turned off in time, and the operation of “starting” combustion can be safely continued. In the event of a forced shutdown or fire, the flame detection system shuts off the gas supply to the burner.

Problems with the flame detection system can cause an annoying shutdown of the burner computer. This leads to a situation of no energy.

A very common flame detection method is commonly referred to as “flame straightening”. A special metal rod is installed in the path of the flame. This is called a “flame catcher” or “rodray of flame.” Rod flames have been found in almost all forced draft combustion systems and in many forced draft burners.

In short, flame system rectification is certainly an electrical process in which a reduced level DC current is passed through the flame and grounded during the flame rod. Technicians can measure this flame current by placing a meter, typically measuring DC microamps, in series with the flame rod.

The ignition controller is programmed to look for this DC current and, based on the strength of this command signal, issues an absolute Go-No-Go signal. Normal flame currents for exhaust burner systems vary by manufacturer and individual system type. A normal signal of 1 microamps DC to 7 microamps DC is common. Also, if the flame current is low or absent, the keypad will stop the ignition process in addition to stopping the gas flow. This eliminates the risk of an explosion.

Why would a flame be flickering on a bunsen burner?

The two strengths of this system are undoubtedly its very fast response (within a few microseconds) that cannot be beaten or beaten. One disadvantage is that the magnitude of the possible flame current is very small and can be easily reduced.

Because the flame rod, the flame and some of the metal parts of the burner are undoubtedly part of a highly competitive electrical circuit, they are subject to the same problems as all electrical appliances. If these components become dirty, rusty, or corroded, all electrical circuits will be damaged and the flame may go out, even if the fireplace has been successfully installed and everything should be working properly.

This results in an annoying shutdown or freeze and no overheating. In this state, you will see the human burner pass through the normal ignition line, ignite the flame, and then go out within a few seconds. Some burners go into repeat mode and repeat the treatment several times. Others remain in effect until the power is restarted. For a short time, until rIf a flame is emitted, you can usually measure the flame signal and find that it is generally weak.

How do you troubleshoot a flame sensor?

Turn off the power to your oven.Close the fuel cock.Remove the fixing screw.Carefully remove the sensor.Check the sensor: if the insulation is intact, but looks dirty, burnt, or partially corroded, it may just need to be cleaned.

This shutdown is a normal response to a low flame signal. The ignition regulator does its job and works and ensures safety.

Flamethrowers usually need to be replaced unless they are physically damaged or broken in some way. Clean the flame rod and burner tip to correct the problem. It may also be necessary to check the quality of the flame, as a weak slow flame or raising a particular burner will also break the flame rectification circuit. The same applies to electrical rod connections and base plate connections.

How do I know if I need a new flame sensor?

The oven turns on but turns off after a few seconds (short cycles)The flame sensor cover is cracked.The burner sensor is covered with soot or corrosion.

Flame rods should be cleaned with a taut steel wire brush or steel wool. Never use sandpaper, a sanitary roller, or other abrasive materials. This will scratch the surface with a fire stick. After cleaning in this unique way, the impurities are quickly filled with scratches, resulting in a flame rodIt gets dirty very quickly again. Flames scratched by flying flames should be considered damaged and should also be replaced.

Speed up your computer today with this simple download.How to repair gas cooktop burners?

What is a power flame burner?

The larger burner is called an “electric burner” and is specially designed for quickly searing meat and boiling water quickly. Medium sized recorders are “general purpose” or “standard” recorders. And the smaller burner, designed as “simmer”, is for slow-cooking food (think delicate work like tempering chocolate).

Solución De Problemas Del Sistema De Llama Y Quemador

Решение по поиску и устранению неисправностей системы горелки и пламени

Rozwiązywanie Problemów Z Palnikiem I Systemem Płomienia

Felsökningslösning För Brännare Och Flammsystem

Solução De Problemas Do Sistema De Queima E Chama

Solution De Dépannage Du Brûleur Et Du Système De Flamme

Fehlerbehebungslösung Für Brenner Und Flammensystem

버너 및 화염 시스템 문제 해결 솔루션

Oplossing Voor Probleemoplossing Voor Brander En Vlamsysteem

Soluzione Per La Risoluzione Dei Problemi Del Bruciatore E Del Sistema Di Fiamma